580 BGA rework table features:

1. Linear slider is used to make the X, Y and Z axes fine-tunable or fast positioning, which has high positioning accuracy and fast operation.

2. The machine adopts the human-machine interface of Taiwan‘s high-definition touch screen, controlled by PLC, and can store multi-group user‘s temperature curve data. It has the function of opening secret code protection and modification. When working, the temperature reflects the data to the touch screen in the form of curve, and has the function of instantaneous curve analysis.

3. Using three-temperature zone to heat independently, hot air heating in upper and lower temperature zones, infrared heating in bottom temperature zones, temperature precisely controlled at +3 degrees, the upper temperature zone can move freely as needed, the second temperature zone can be adjusted up and down, and the upper and lower heaters can set up multi-stage temperature control at the same time. The output power of IR preheating zone can be adjusted according to actual requirements.

4. The hot air nozzle can rotate 360 degrees. The bottom infrared heater can make the PCB plate heat uniformly.

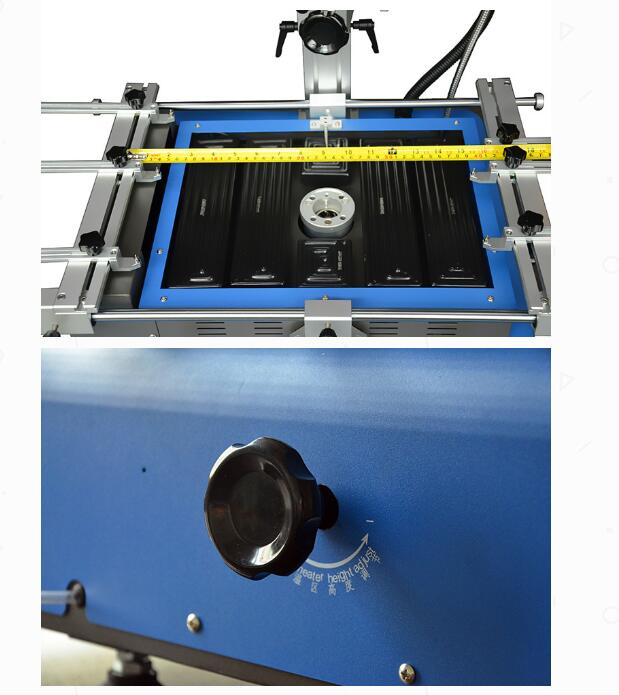

5. Closed-loop control of high-precision K-type thermocouple and external temperature measurement interface are used to realize precise temperature detection. The positioning of PCB board adopts V-groove. The flexible and convenient movable universal fixture protects PCB board, prevents damage of edge devices of PCB and PCB deformation, and can adapt to repairs of various BGA package sizes.

6. High-power cross-flow fan is used to quickly cool PCB board and improve work efficiency. Meanwhile, a vacuum pump and an external vacuum suction pen are built in to facilitate and quickly pick up the BGA chip.

7. Welding work has alarm function after completion. In order to facilitate users‘use, the function of "early alarm" has been added.

8. This machine is certified by CE and equipped with emergency stop switch and automatic power-off protection device for abnormal accidents. When the temperature is out of control, the circuit can automatically power-off and has double over-temperature protection function.

Technical parameters of BGA rework table:

Total power 4800W

Upper heating power 800W

Lower heating power 1200W

Infrared heating power of lower part 2700W (1200W controlled)

Single Phase AC 220V+1050Hz

Positioning mode V-shaped chute + universal fixture

Closed Loop (Closed Loop) with high precision K-type thermocouple (Ksensor) for temperature control can measure temperature independently up and down to 3 degrees.

Electrical Material Selection Touch Screen+Temperature Control Module+PLC Programmer

Maximum PCB size 410 x 380 mm

Minimum PCB Size 10 x 10 mm

Number of Temperature Measurement Interfaces 1

PCB thickness 1-6 mm

Applicable chip 1mm-6cm

Shape size 630 x 630 x 650 mm

The net weight of the machine is 45kg